Power meters, like most cycling products, are subject to huge marketing efforts that do their best to part you with your money.

They are definitely a useful addition to any serious cyclist’s arsenal but the marketing and promotional material only tell half the story.

If you’re in the market for a power meter or are beginning your research into them, you’re on the right page.

Here are 10 things about power meters that you might not know, yet.

1. There's A Steep Learning Curve

While simple in their design, using a power meter to its full potential requires a lot of research and perhaps even professional input from a coach. Analyzing and interpreting the data demands almost as much effort as the rides themselves.

Read More : 5 Reasons Why You Don’t Need A Power Meter

A typically structured training plan using power data will require you to learn about wattage, average power, peak power, normalized power, Intensity Factor, and a bunch of other potential new terms.

Then there are the charts and metrics generated from those data such as Training Stress Score that monitors your condition, fitness, and fatigue. The Training Stress Score is made up of the Acute Training Load for fatigue, Chronic Training Load for fitness, and Training Stress Balance for form.

If you haven’t trained with power before, you’re going to need to learn how to interpret all this data and learn a bunch of new acronyms!

2. You Might Turn into A Data Geek

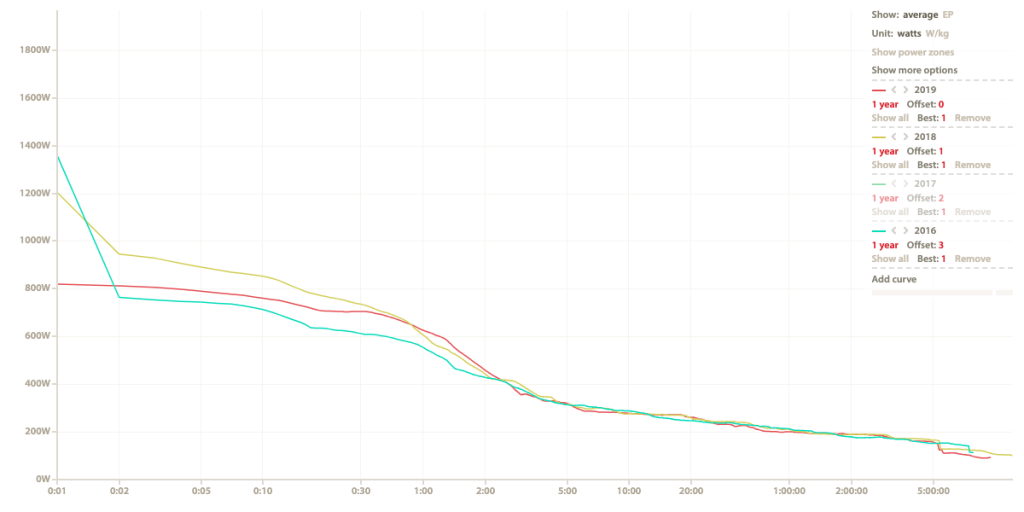

To make sense of all that data, you’re going to have to learn to love numbers and charts.

We love cadence, elevation, speed, distance, heart rate, calories, and more as part of our sport. But, using power meter data takes that to a whole new level!

The Training Stress Score, Acute Training Load, Chronic Training Load, Training Stress Balance, and more will all be made up of data. Add in your power numbers for 5, 15, 30 seconds, 1,2, 5, 15, 60 minutes, FTP, the power to weight, leg balance, and all the other measurements involved in training to power, and you could quickly become overwhelmed.

Read More : The 4 Most Popular Cycling Analytics Softwares

Learning how to use this data effectively is one thing. Resisting the urge to talk about it all during a coffee shop is something else.

You really don’t want to be that guy!

3. Power Readings can be Erratic

One of the advantages of using power meters is instant access to accurate data.

On the other hand, it’s also easy to become obsessed with riding to numbers or become confused when your bike computer begins spewing fast-moving, seemingly erratic readings on the screen.

While we would all like to be as strong as Chris Froome, we also don’t want to ride like him. Riding to power during a race is an exceptional way to pace yourself over the distance and ensure you have enough left in the tank for the sprint or hill finish.

In any situation other than a race, you’ll miss the scenery or miss out on chat and banter with your ride buddies if you constantly stare down at your screen.

If you’re going to use a power meter, you should ideally set your bike computer to show a 3-second power average rather than real-time. This will slow and smoothen the data deluge and make the power reading more manageable, and not all over the place!

Read More : Wahoo Elemnt vs Bolt vs Roam – What’s the Difference?

4. Power Meters will Never Agree with Each Other

All power meters will tell you they are accurate to +/- 2% or thereabouts. That’s fine for most of us and even the pros.

You could use a Stages power meter on one day and an SRM on the next and you could end up having two different readings for exactly the same ride, with all things being equal.

The two readings should be very similar but that isn’t always the case.

Again, for most of us, this isn’t an issue as it is very unlikely we would be riding one brand of power meter one day and a different one the next. Neither do we need to be exact enough in our data that +/-2% presents a problem.

However, it is one of the many things about power meters that many people didn’t know about.

5. Power Meters are not 100% Accurate

Building on that point above, no power meter currently on the market is 100% accurate. The +/-2% figure is an average of discrepancy across the range.

Each individual make and model of power meter usually lists their accuracy somewhere in the product documentation or on the website.

For example, the Quarq Dzero claims to be accurate to +/- 1.5%. The Stages G2 is accurate to +/- 2%, the PowerTap GS Rear Hub +/- 1.5%.

You get the idea.

Some power meter manufacturers are quite clear about the expected accuracy. Some are not so forthcoming and will take a little drilling down to get what you need.

An accuracy of between 1-2% for most cyclists is not going to be an issue. It is still way more accurate than just riding with a heart rate monitor. Just don’t buy a power meter expecting 100% accuracy because at the moment, that doesn’t exist.

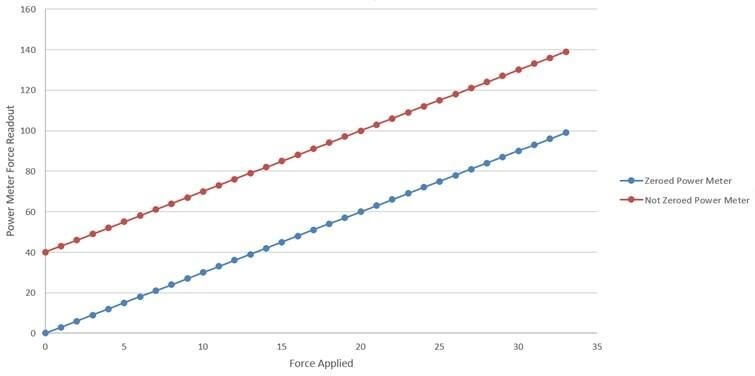

6. Zero Offset

One thing you rarely see in the marketing material for power meters is the requirement for zero offset calibration. To add to this, different power meters perform the zero offset calibration in different ways.

Zero offset calibration is the process of zeroing the power meter so it knows where to measure from. It’s very similar to zero-ing your bathroom scale to ensure that the reading starts at zero.

This increases the accuracy of the power meter by giving it an absolute zero baseline from which to measure your wattage.

For example, you can perform a zero offset on the Quarq power meter from your bike computer, or through pedaling backward for five revolutions. For Power2max, zero offsets are done automatically when you stop pedaling for 3 or more seconds.

The act of manually doing a zero offset is very straightforward. It’s the remembering to do it that’s the hard bit!

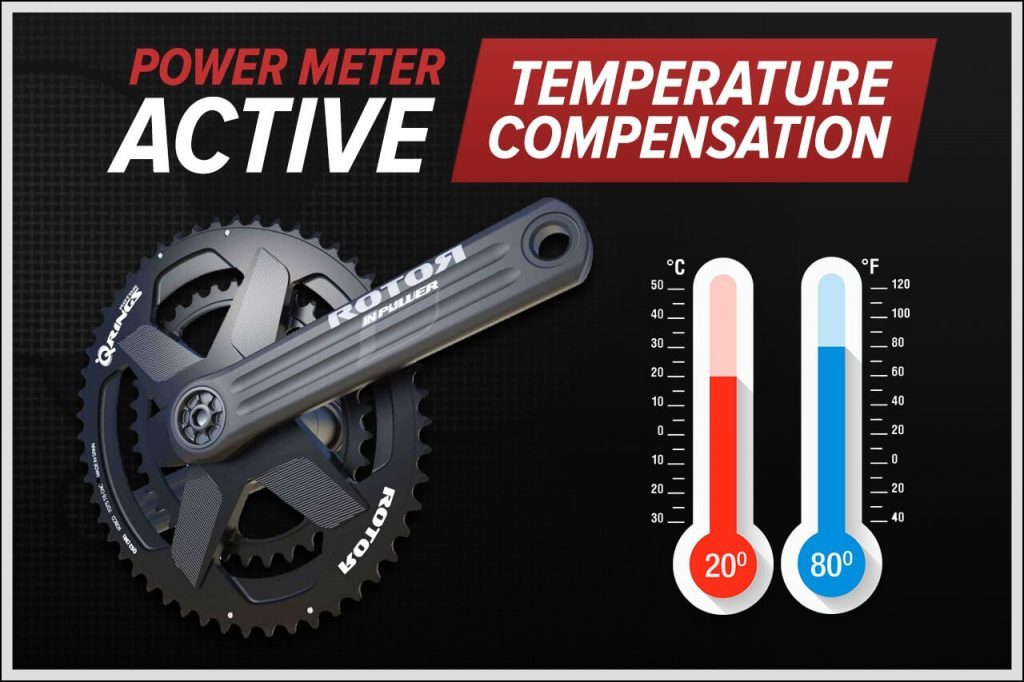

7. Power Meters are Susceptible to Temperature Changes

Power meters are quite susceptible to temperature changes too. This is something else the marketing materials sometimes don’t mention.

Power meters work using strain gauges, and changes in temperature can influence their readings. Due to the microscopic nature of strain gauges, any drastic changes in temperature can affect the data it generates.

Strain gauges are tiny electronic instruments that measure variations in electrical resistance caused by pressure. The gauge will use a mixture of metals that deform in a predictable way when power is applied to it. The gauge then measures this deformation through changes in electrical resistance and uses math to convert this into an accurate measurement in watts.

So how does temperature affect the measurements?

Temperature changes can cause those metals to either deform faster when warmer and slower when colder, altering the electrical resistance. Newer power meters do take temperature changes into account when building their strain gauges.

If you come across terms like active temperature compensation, then you know that the power meter is built to handle the type of situation.

Read More : Power Meter Active Temperature Compensation Explained

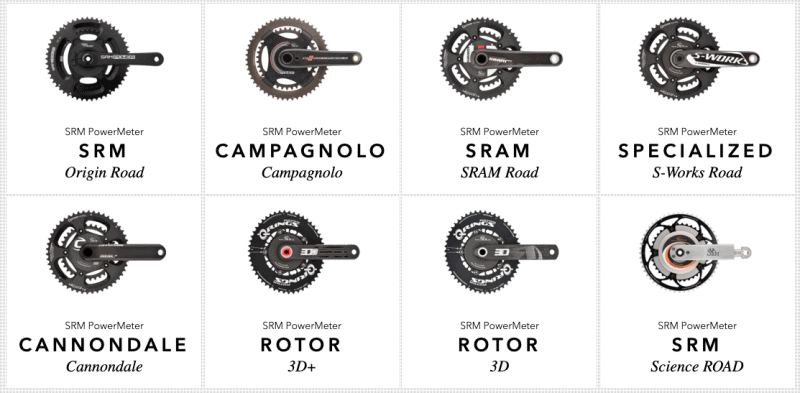

8. Crank Arm Compatibility

Power meters come in all shapes and sizes – hub, pedal, crank arm, and crank spider. It is this latter that can lead to confusion.

Crank spider-based power meters such as SRM, Power2Max, and Quarq have different fitments for different crank arms. You will notice that they offer the same model of power meter for different crank arms such as for Shimano, Campagnolo, SRAM, Cannondale, Specialized and so on.

You will need to make sure you get the correct power meter for the crank arm that you’re using, otherwise, it won’t fit. It’s a small thing but can make the difference between riding right away or getting frustrated waiting for a new replacement model.

Read More : Buyer’s Guide for Cycling Power Meters

9. There's A Built in Cadence Sensor

Newer power meters come with built-in cadence sensors as part of the package.

They use various methods as simple as a magnet or more advanced technologies like an accelerometer or CPS (Crank Positioning System) to calculate the cadence.

If you already have a cadence sensor on your bike, this may not be a bonus feature.

If you don’t, it might. As cadence forms part of a structured training program, cadence data can form part of your training and influence efficiency and pace over longer rides.

10. Maintenance

The final point that not many people know about power meters until they own one is maintenance.

Some models are very easy to maintain with standard CR2032 (Quarq, Stages) or CR2550 (Power2Max) batteries that you can change yourself. Newer models are USB rechargeable, which makes things even easier.

Alongside the zero offsets mentioned earlier, that’s all the maintenance your power meter needs.

Other models need a little more care. For example, older SRM power meters, for example, have no user-serviceable battery. They use proprietary batteries that cannot be changed at home.

You have to send the power meter back to SRM for a replacement which can take a couple of weeks and cost you around $150. The good thing is, the power meter is serviced and calibrated at the same time.

Newer SRM models include user-serviceable batteries now thank goodness!

Summing Things Up

The purpose of this piece is not to put you off buying a power meter.

It is designed to fill in the gaps that most product marketing carefully ignores or omits.

None of these ten points should put you off buying a power meter if you want one.

People make better buying decisions when in full ownership of the facts and if you’re planning to spend north of $500 on a power meter, you have better know what you’re getting yourself into.